Parts and accessories for Trans Ams, Fieros and Corvettes

|

||||

Parts and accessories for Trans Ams, Fieros and Corvettes |

||||

|

|

|

|

|

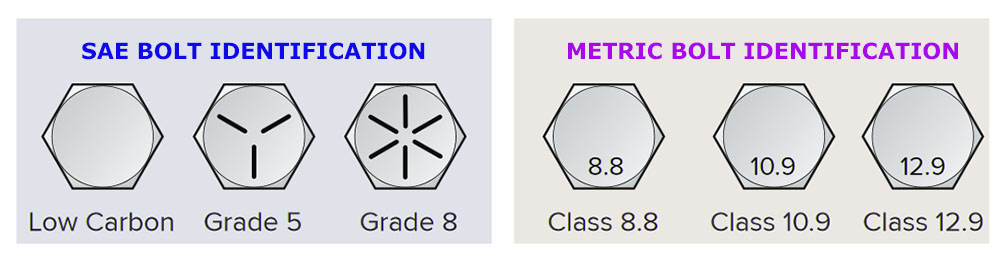

GENERAL BOLT INFORMATION |

|

|

|

|

SAE GENERAL BOLT TORQUE |

||||||||

| LOW CARBON | GRADE 5 | GRADE 8 | STAINLESS (18-8) | |||||

| PITCH | COARSE | FINE | COARSE | FINE | COARSE | FINE | COARSE | FINE |

| 1/4" (20/28) | 4 | 5 | 6 | 7 | 9 | 10 | 6 | 8 |

| 5/16" (18/24) | 8 | 9 | 13 | 14 | 18 | 20 | 11 | 12 |

| 3/8" (16/24) | 15 | 17 | 21 | 26 | 33 | 37 | 20 | 22 |

| 7/16" (14/20) | 24 | 27 | 37 | 41 | 52 | 58 | 31 | 33 |

| 1/2" (12/20) | 37 | 41 | 57 | 64 | 80 | 90 | 43 | 45 |

Bolt torque is in lb-ft. Values are rounded to the nearest whole number. These are suggested values when no torque specification is available through a factory service manual. Although stainless is stronger than a non-graded bolt, it is weaker than most bolts used in the automotive industry, and should never be used in any structural, brake, suspension or chassis application, no matter how attractive they look! Rod, main and head bolts should always be consulted with a factory service manual for proper torque. |

||||||||

METRIC GENERAL BOLT TORQUE |

||||

| GRADE 8.8 | GRADE 10.9 | GRADE 12.9 | STAINLESS (18-8) | |

| M6x1.0 | 8 | 11 | 13 | 5 |

| M8x1.25 | 19 | 27 | 31 | 11 |

| M10x1.5 | 37 | 53 | 62 | 18 |

| Bolt torque is in lb-ft. Values are rounded to the nearest whole number. These are suggested values when no torque specification is available through a factory service manual. Although stainless is stronger than a non-graded bolt, it is weaker than most bolts used in the automotive industry, and should never be used in any structural, brake, suspension or chassis application, no matter how attractive they look! Rod, main and head bolts should always be consulted with a factory service manual for proper torque. | ||||

|

(C) 2021, Nook and Tranny LLC |